Rust can make even the strongest metal look weak and worn out. Once moisture and oxygen meet metal, corrosion creeps in fast.

You can remove rust from metal safely and restore its clean surface using simple tools, natural ingredients, or specialized products.

Here’s what you need to know: how rust forms, how to handle it safely, and which methods actually work. You’ll see options ranging from sanding and wire brushing to natural fixes like vinegar or lemons.

For tougher jobs, chemical and professional techniques can stop corrosion and help protect metal from future damage. It’s worth understanding how rust works and what you can do to prevent it, so your metal stuff stays strong and ready to use.

Understanding Rust and Its Impact

Rust weakens metal by changing its chemical structure and surface strength. Knowing what causes rust and how iron oxide forms lets you protect your metal stuff before it’s too late.

What Causes Rust on Metal

Rust forms when iron or steel reacts with oxygen and moisture. This reaction, called oxidation, creates that reddish-brown layer known as iron oxide.

Damp or salty environments speed up the process, so coastal areas and humid spaces are prime rust territory. Even tiny scratches or chips in paint can expose bare metal to air and water.

Once that happens, oxidation starts to spread under the surface.

Common conditions that trigger rust include:

- High humidity or frequent rain

- Salt exposure, especially road salt or seawater

- Poor ventilation, trapping moisture around metal surfaces

When you know these causes, you can do things like seal, paint, or dry metal to help prevent corrosion. If you want a deeper dive, How to Remove Rust from Metal (Learn Effective Ways) is a solid read.

How Iron Oxide Forms

When water and oxygen hit iron, electrons move from the metal to the oxygen atoms. That reaction makes iron oxide, which is the flaky stuff we call rust.

It’s not a one-step process. First, iron dissolves a bit in water and releases ions.

Oxygen combines with those ions to form hydrated iron oxide. This compound expands, cracks the surface, and exposes more metal beneath.

Different metals rust at different speeds. For example, steel rusts faster than stainless steel because it doesn’t have protective chromium.

Once rust starts, it doesn’t stop unless you step in. Getting rid of it early keeps your metal strong and decent-looking.

Why Rust Removal Is Important

Getting rid of rust protects metal from more damage and keeps it durable. If you ignore it, iron oxide eats away at the surface and can make metal brittle or even dangerous.

Clean metal just works better. Tools, machines, and vehicles all function more smoothly without corrosion dragging them down.

Regular maintenance saves you from shelling out cash for repairs or replacements. You can remove rust from metal with stuff like vinegar or baking soda, or by using commercial rust removers.

If you want a step-by-step, check out 7 Easy Ways for Rust Removal From Metal Without Causing Damage.

Essential Tools and Safety Precautions

You’ll need the right tools and safe working conditions to get rust off effectively. Good prep and gear protect you from debris and chemicals, and they help you get better results.

Protective Gear and Workspace Setup

Always put on safety goggles, gloves, and a dust mask to keep your eyes, hands, and lungs safe from rust bits and chemical fumes. If you’re using acids or commercial removers, go for nitrile or rubber gloves.

Make sure your workspace is well-ventilated. Open a window or set up a fan, especially if you’re using things like phosphoric acid or vinegar-based cleaners.

MachineMFG’s rust removal guide points out that good airflow means you’re less likely to breathe in nasty fumes.

If you’re using power tools like grinders or drills, keep a fire extinguisher close. Sparks can happen, and you don’t want to take chances.

Set up a sturdy table, non-slip mats, and decent lighting. A clean, stable space helps you focus and keeps accidents to a minimum.

Recommended Tools for Rust Removal

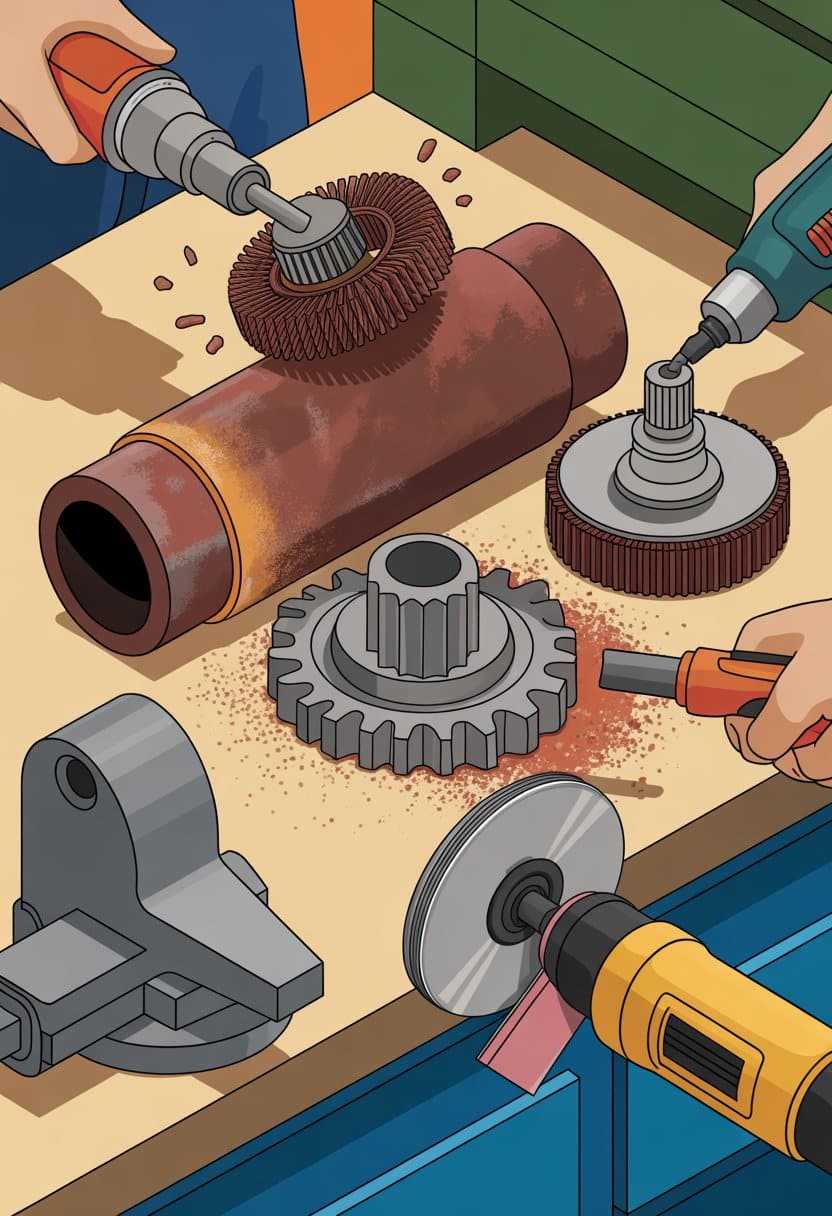

Pick your tools based on how much rust you’re dealing with. For light rust, grab wire brushes, sandpaper, or abrasive pads.

Start with coarser grit and work your way to finer for a smoother finish. For heavy rust, power tools like drills with wire brush attachments or angle grinders save time.

Always follow the tool’s safety instructions and wear your gear. Keep chemical rust removers or natural solutions like vinegar and baking soda handy.

wikiHow’s guide on removing rust from metal says household acids can do the trick without hurting the metal if you use them right.

You might want rags, containers for soaking small parts, and protective coatings like rust-inhibiting primer or oil to keep rust from coming back.

Preparation Steps Before Cleaning

Check the metal before you start. Is it just a little surface rust, or is it deep corrosion?

Light rust usually comes off with gentle scrubbing. Heavy rust might need chemicals or power tools.

Wipe the surface with a dry cloth to get rid of dust and loose flakes. This makes any rust remover you use work better.

Cover anything nearby with plastic or drop cloths to avoid splashes. If you’re working on tools or small parts, label and separate everything before you soak it.

Read all product labels and safety instructions. Whether you go with vinegar, commercial removers, or electrolysis, a little prep makes the job safer and easier.

Mechanical Rust Removal Methods

Mechanical rust removal means using tools and abrasives to scrape or grind corrosion off metal. Manual methods work for small stuff, while power tools help with bigger areas.

The trick is to get rid of the rust without messing up the metal underneath, especially if it’s delicate or thin.

Using Sandpaper and Steel Wool

Sandpaper and steel wool give you a gentle rust removal option with good control. Start with coarse sandpaper (about 80–120 grit) to cut through heavy rust, then move up to finer grits (up to 400) for smoothing.

Use steel wool (#0000 grade) for light rust or finishing touches. It polishes the metal without leaving scratches.

Apply steady pressure and sand along the grain of the metal to avoid marks. This works great for small tools, handrails, or furniture hardware.

Always wipe away dust and debris after sanding, then dry the surface completely to keep new rust from forming.

Wire Brushes and Drill Attachments

Wire brushes take off rust fast from big or uneven surfaces. Try a handheld wire brush for small jobs, or a drill-mounted wire wheel if you want to move quicker.

The spinning action helps you get into corners and textured spots that sandpaper can’t reach. Use brass or stainless-steel bristles for softer metals to avoid scratches.

For tough jobs, carbon steel brushes have more bite. Keep the drill at a moderate speed so you stay in control and the metal doesn’t get too hot.

Wear safety goggles and gloves—flying debris isn’t fun. MachineMFG’s guide on rust removal says wire brushing works well for moderate corrosion if you suit up right.

Aluminum Foil Technique

The aluminum foil technique is a cheap, easy way to remove light rust from chrome or steel. Just dip a small piece of foil in water or vinegar and rub it over the rusty spot.

The foil acts as a mild abrasive, and the liquid helps dissolve the rust. As you rub, you’ll see a fine paste form—wipe it off with a soft cloth.

This method is especially handy for bicycle parts, car bumpers, and tools where you want to keep the shine. Aluminum is softer than steel, so you won’t scratch the surface.

It’s perfect for gentle cleaning and bringing lightly rusted metal back to life.

Natural and Homemade Rust Removers

You can actually get rust off metal with stuff you probably already have at home—vinegar, lemon juice, and baking soda. These natural methods use mild acids and abrasives to loosen rust but won’t harm the metal.

Vinegar and Baking Soda Solutions

White vinegar works as a mild acid that dissolves rust. You can use it by itself or mix it with baking soda for extra cleaning power.

To make a simple homemade rust remover, just pour white vinegar into a container big enough for your rusty item. Let it soak for a few hours or overnight.

The acid in the vinegar reacts with the rust and loosens it. After soaking, scrub with a brush or steel wool.

Rinse the item with water mixed with baking soda—this neutralizes the acid and helps stop more rust from forming. Dry it completely and maybe add a protective coating so rust doesn’t come back.

Curious about the details? Here’s a vinegar and salt rust removal method that breaks it down.

Lemon Juice and Salt Method

Lemon juice has citric acid, which naturally dissolves rust. When you combine it with salt, you get a gentle abrasive paste.

Sprinkle salt on the rusty spot, then squeeze fresh lemon juice over it until the salt is wet. Let it sit for a couple of hours.

The acid does the heavy lifting while the salt adds some scrubbing action. Use a brush or cloth to scrub, then rinse with water and dry.

This works well for small tools, kitchen stuff, and decorative pieces. If you want more natural options, check out this guide to rust remedies.

Potato and Dish Soap Approach

A raw potato has oxalic acid, which reacts with rust. Cut a potato in half and put dish soap or baking soda on the cut side.

Press the potato onto the rusty area and rub gently. The acid and soap work together to dissolve rust, and the potato’s starch acts as a mild abrasive.

After a few minutes, rinse the metal and dry it all the way. This is great for flat or lightly rusted surfaces.

It’s safe for cookware and utensils since you’re only using food-safe stuff. For more quirky natural ideas, Tips Bulletin’s homemade rust remover recipes are worth a look.

Baking Soda Paste Technique

Baking soda gives you a non-toxic way to tackle light rust. Mix baking soda and water into a thick paste, then spread it over the rusted spot.

Let the paste sit for about an hour. That gives it time to soften the rust.

Scrub the surface with a brush or a bit of aluminum foil dipped in the paste. This gentle abrasion lifts rust without scratching the metal.

Rinse thoroughly and dry the item right away.

This method works best for delicate or thin metal pieces that stronger acids might damage. If you want more ideas, check out these natural rust removal methods.

Chemical and Commercial Rust Removers

Chemical rust removers use controlled reactions to dissolve corrosion. They’re designed to target iron oxide without harming the base metal.

You’ll find both acid-based and acid-free options. Each works best for different levels of rust and types of metal surfaces.

Oxalic Acid Applications

Oxalic acid does a solid job on light to moderate rust. It’s handy for small items like tools, cookware, or hardware.

You’ll usually find it as a powder or liquid. Mix it with water to create a cleaning solution.

Apply the diluted solution with a brush or cloth. Let it work for 15–30 minutes.

The acid reacts with rust and forms a water-soluble compound you can rinse away. Always wear gloves and goggles—oxalic acid can irritate your skin and eyes.

This method works for stainless steel and iron. Don’t use it on aluminum or painted surfaces.

For more details, check out these step-by-step instructions for removing rust from metal.

Phosphoric Acid Treatments

Phosphoric acid pops up in many industrial and household rust removers. It converts rust into iron phosphate, which forms a dark, stable layer that helps prevent more corrosion.

This is especially useful if you plan to paint or coat the surface afterward.

Apply phosphoric acid with a brush, spray, or cloth. Let it react for 30–60 minutes depending on how thick the rust is.

When the surface turns black or gray, rinse and dry it completely before priming or painting.

Because it both removes and stabilizes rust, phosphoric acid is a favorite in automotive and marine maintenance. There’s more on chemical rust removal if you’re curious about delicate or big jobs.

Store-Bought Rust Remover Options

Commercial rust removers come ready to use. You’ll see liquids, gels, and sprays that use acids, chelating agents, or tannic acid converters to lift or neutralize rust.

Popular brands often offer “acid-free” or “non-toxic” options that are safer for indoor use. They work well on tools, bikes, and fixtures without leaving harsh fumes or residue.

When you’re picking a store-bought rust remover, check the label for the type of metal and recommended application time. If you want comparisons, here are the best rust removers of 2025.

Advanced and Professional Rust Removal Techniques

You can remove rust from metal using advanced methods that go beyond basic scrubbing or chemical soaking. These techniques use electricity, chemical reactions, or high-energy light to restore metal surfaces with precision.

Electrolysis for Rust Removal

Electrolysis uses an electrical current to separate rust from metal. Submerge the rusted item in a water and washing soda solution, then connect it to a DC power source.

The rust moves from the metal to a sacrificial anode, leaving the surface clean. This method works well for tools, automotive parts, and antiques.

It removes rust evenly and preserves fine details. You’ll need a plastic container, battery charger, washing soda, and a steel or iron anode.

Steps:

- Mix 1 tablespoon of washing soda per gallon of water.

- Attach the negative lead to your item and the positive to the anode.

- Run the current for several hours until rust loosens.

- Rinse and dry immediately to prevent flash rust.

Electrolysis is a cost-effective way to restore metal without abrasion or chemical fumes.

Rust Converter Products

A rust converter changes iron oxide into a stable black coating that prevents further corrosion. These products contain tannic acid and organic polymers that react with rust to form a protective layer.

You can apply them with a brush or spray on lightly rusted surfaces. They’re useful when full rust removal isn’t practical.

Once cured, you can paint or seal the surface. Common brands come in liquid or aerosol form for easy use.

Advantages:

- Stops rust progression

- Creates a paintable surface

- Reduces preparation time

If you want more info, check out Bob Vila’s guide on rust removal methods.

Laser Rust Removal Services

Laser rust removal uses a concentrated beam of light to vaporize rust without touching the base metal. The process is precise and clean—ideal for high-value parts or industrial equipment.

It works by heating the rust layer until it breaks apart and lifts away. The underlying metal stays intact because the laser’s wavelength targets only oxidized material.

Key Benefits:

- No chemicals or abrasives

- Minimal waste generation

- Suitable for delicate or complex shapes

Professional providers use handheld or automated laser systems. You can see examples of laser rust removal in industrial settings.

How to Prevent Rust on Metal

Keeping metal free from rust means blocking moisture, limiting oxygen exposure, and maintaining clean, dry surfaces.

You can reduce corrosion by applying protective coatings, storing metal properly, and controlling the environment where it’s kept.

Protective Coatings and Sealants

Covering metal with a protective layer stops oxygen and water from reaching the surface. Paint, oil, wax, and specialized rust inhibitors form barriers that slow oxidation.

Applying a rust converter or primer before painting can neutralize early rust and create a base layer for protection.

For outdoor items, use galvanization, which coats steel or iron with zinc. This layer sacrifices itself first, keeping the underlying metal intact.

You can also use powder coating for durable, long-lasting coverage that resists chipping and moisture.

When working with tools or machinery, wipe them clean and add a thin film of machine oil after each use. This simple step prevents rust buildup, especially in humid areas.

If you want more on coatings, check out Armor Protective Packaging®.

Proper Storage and Maintenance

Store metal in dry, ventilated spaces to prevent trapped humidity. Avoid placing items directly on concrete floors, which can hold moisture.

Use wooden pallets or rubber mats to lift metal objects off the ground.

Create a regular cleaning schedule. Remove dirt, grease, and old coatings with mild soap and water, then dry thoroughly.

Dust and grime can trap moisture and speed up corrosion. If you notice small rust spots, sand them away and reapply a sealant right away.

For vehicles, bikes, or tools kept in garages, use dehumidifiers or silica gel packs to keep moisture low. According to MFG Shop, proper storage methods extend the lifespan of metal items and reduce maintenance costs.

Environmental Control Tips

Humidity, temperature changes, and air pollutants all mess with how fast rust creeps in. Try to keep indoor humidity under 50% by using dehumidifiers or air conditioners.

If you’re dealing with metal outdoors, grab some weatherproof covers to block rain and condensation. Living near the ocean? Salt in the air can really speed up corrosion.

Rinse metal surfaces regularly to get rid of salt residue. In industrial spaces, put in ventilation systems to cut condensation and keep the air moving.

You can also use corrosion inhibitors in storage or shipping areas. These chemicals form a thin layer on metal that slows down oxidation.